If you’ve been researching a solution to automate material movement in your factory, you have likely come across the term “vacuum gripper.” This type of robotics technology has become one of the most popular solutions for tasks such as machine tending, CNC machining operations, and more. Industry professionals love it because its efficient design allows it to move materials quickly and precisely with little programming necessary.

In this article, we will take an in-depth look into what vacuum grippers are, how they work, and the various applications they can be used for. So sit back and get ready—you’re about to learn everything you need to know about this revolutionary material handling system.

Table of Contents

What Are Vacuum Grippers?

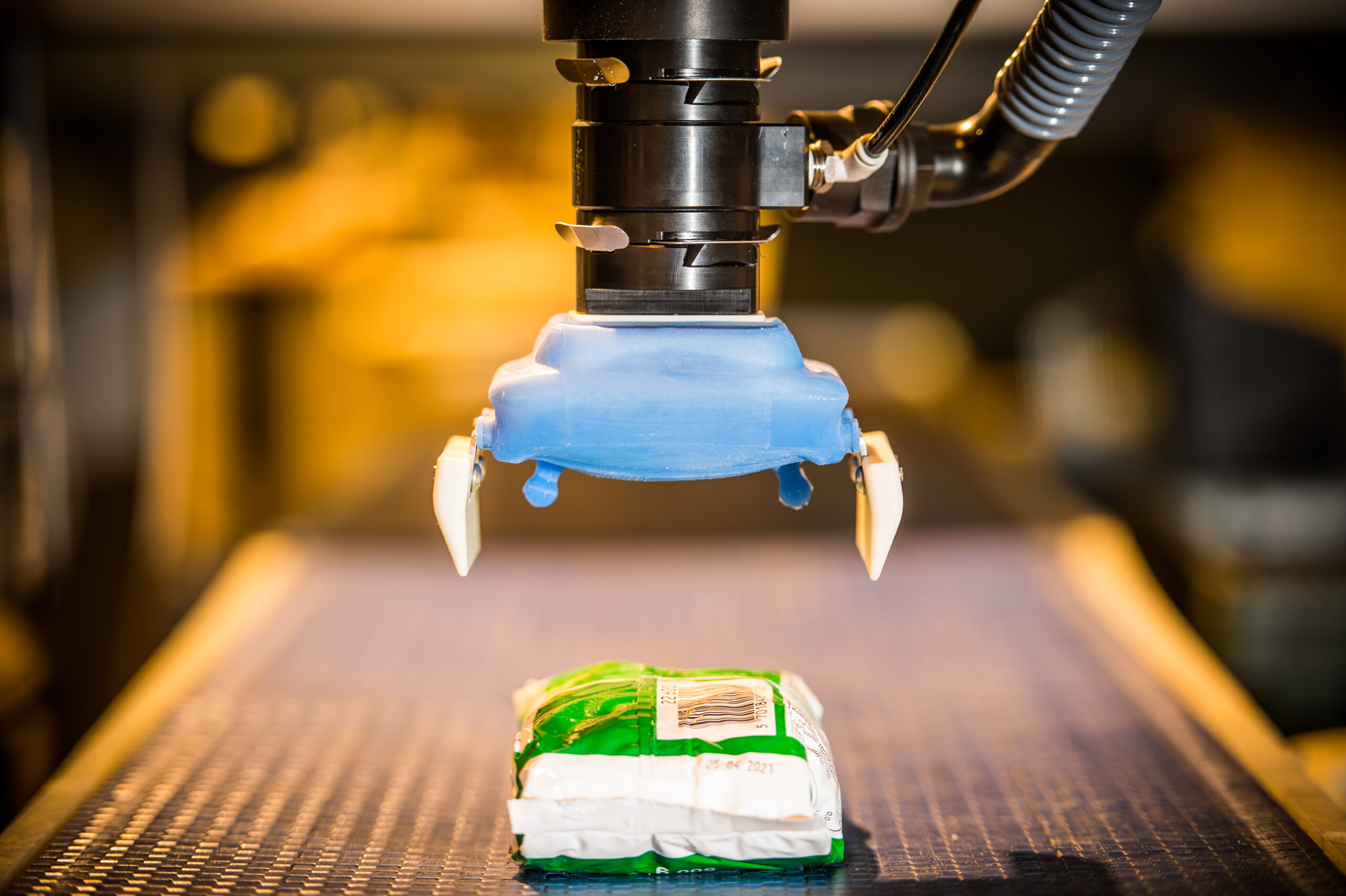

Vacuum grippers are a handy tool that does quick work out of handling materials in tight spaces. They offer a unique solution to the problem of manipulating just about any conceivable object without human contact. Vacuum grippers suck the surfaces of objects into its body so that they can be handled quickly and safely. It means that robotic arms don’t have to handle heavy, irregular objects with their hands, saving time and energy – and making delivery operations much faster and more efficient.

Furthermore, thanks to its robotic capabilities, it is perfect for jobs as diverse as packaging, production tasks, assembly lines, material transport, construction sites, and maintenance services. So if you’re looking for an effective way to handle complex materials or automate delicate tasks, vacuum grippers are worth considering.

What Are Vacuum Grippers Used For?

Vacuum grippers can be used in many industries and applications. As mentioned earlier, vacuum gripper technology is excellent for tasks that require precision and speed. It makes them a perfect choice for tending machine operations, CNC machining, or any task involving delicate parts with complex shapes. They are also highly versatile since they can handle a variety of materials with different textures and surfaces, including wood, plastic, metal, fabric, paper, and more.

Because vacuum grippers can hold irregularly shaped pieces such as long tubes or wires without damaging them, they are ideal for gripping objects in tight spaces where other robots would struggle. Thanks to their vacuum power, vacuum grippers can pick up heavier items than traditional robots.

In addition, vacuum grippers are also commonly used in manufacturing lines to transfer items between workstations. By using vacuum suction, they can move heavy pieces quickly and accurately, making them an ideal choice for factories that need to move materials quickly and accurately.

How Do Vacuum Grippers Work?

At the heart of vacuum grippers is a specially designed vacuum system. This system consists of a pump, suction cups, hoses, and various valves to control the pressure and flow of air. The pump creates a vacuum that sucks materials into the suction cups. The suction cups are then attached to robotic arms or other machines, allowing them to grip and move objects quickly and accurately without human contact.

Besides the pump system, many modern vacuum grippers also have built-in sensors that provide additional feedback, such as how much force is being applied during movement, what direction it is moving in, and more. It allows for exact control when manipulating complex objects with intricate shapes.

What Are The Advantages Of Vacuum Grippers?

Vacuum grippers offer many advantages over traditional robots. For starters, they are faster and more precise than conventional robotic arms, allowing for incredible speed and accuracy in material handling tasks. Additionally, the vacuum system enables them to efficiently handle heavier items, making them perfect for material transport applications.

Vacuum grippers also have the advantage of being able to grip irregularly shaped objects without causing any damage or deformation, something that is difficult for most robot arms. They are ideal for manipulating delicate parts such as wires or cables without damaging them.

Finally, thanks to their built-in sensors and feedback systems, modern vacuum grippers can provide detailed information about how much force is being applied and what direction the object is moving. It makes them perfect for applications that require precise control and manipulation of objects.

What Are The Disadvantages Of Vacuum Grippers?

Despite their many advantages, vacuum grippers have a few potential disadvantages. Firstly, they require more setup and maintenance than traditional robots, as the vacuum system needs to be regularly checked and maintained. Additionally, they require more power than traditional robots, so they may not be suitable for locations where electricity is scarce.

Finally, due to their reliance on a powerful vacuum system, vacuum grippers can struggle with thin or lightweight materials that need to create enough suction to keep the object in place. They may only be suitable for some applications where delicate materials must be handled without damage.